Scandicurb

Commercial Kerbing

Process

Kerb Styles & Colours

Gallery

2022 PACKAGES

Concrete reduction

Contact Us

Our ScandiCurb machines are the only machines in the world that are manufactured with both residential and commercial kerbing in mind.

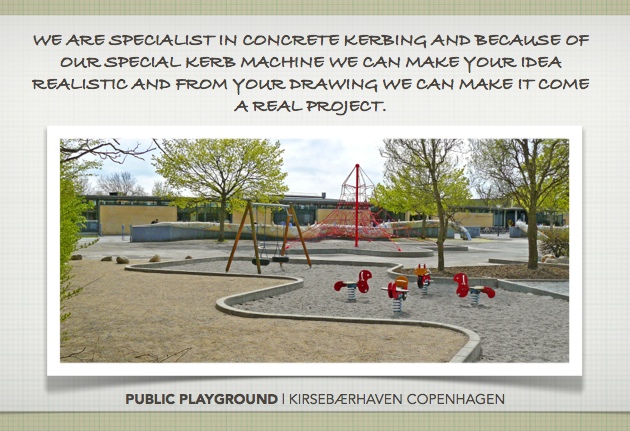

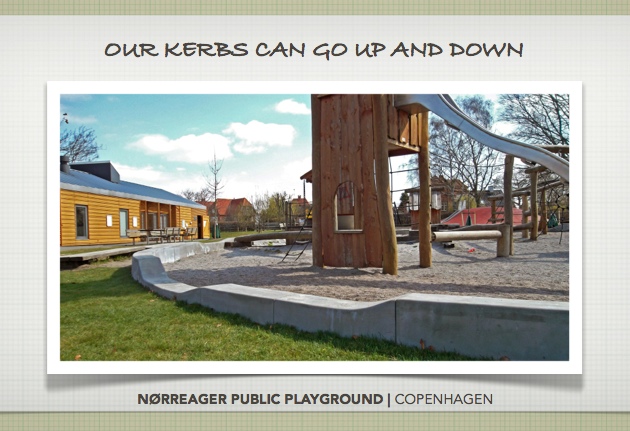

Here we ‘kerbed’ a playground last year for the city of Copenhagen, Denmark. All 336 meters kerbs are 15 cm wide x 30 cm high. A great design by Landscape architects Johansson Landskab.

KantDesign has undertaken more and more commercial kerbing work over the past year.

We believe, and now know, that the potential income from commercial kerbing over residential is a bonus on two sources:

- With commercial kerbing you can install a higher value of kerbs in the same time!

- Commercial kerbing is ALL YEAR ROUND, unlike the perceived ‘Summer season’ of the residential market.

Laying of 28cm x 15 cm kerbs. 336 meters lengh in total! The project design was commissioned by Johansson Landscapes.

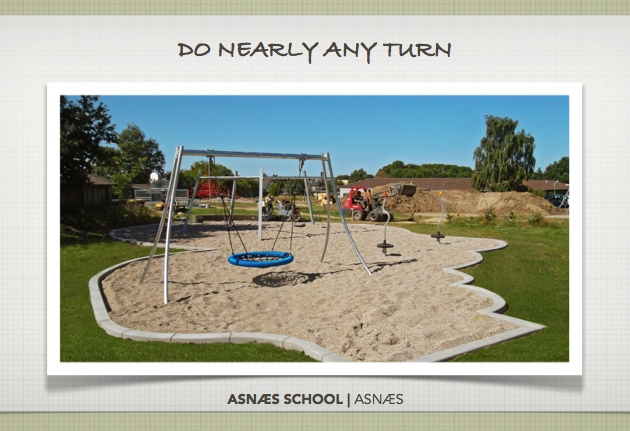

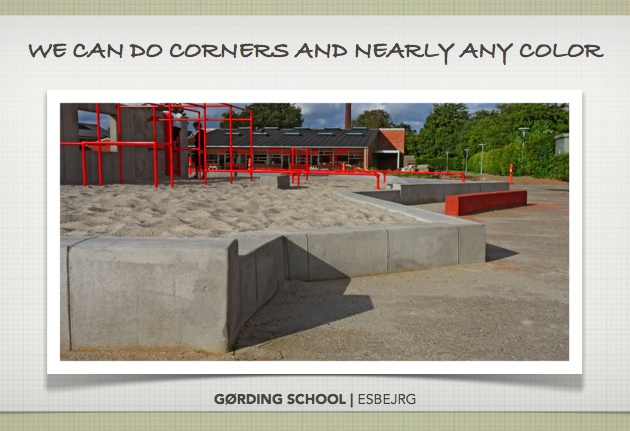

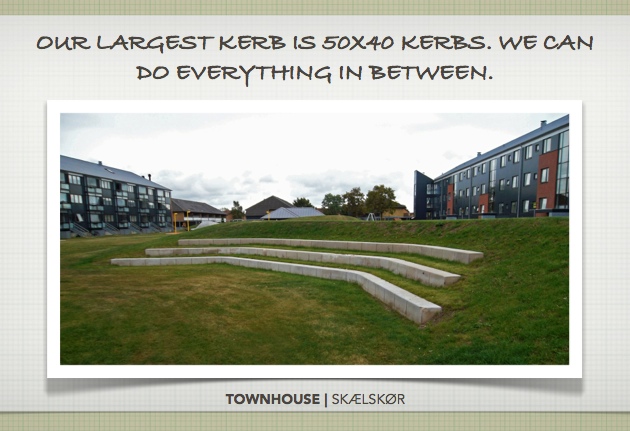

Any angle, turns or basic straight lines are possible with our ScandiCurb machine, with sizes up to 30x15kerbs.

Our commercial customers are very pleased with our unique kerbing system. Why?

- They are very flexible

- We save about 50% concrete compare to traditional cast kerbs

- Can be installed in limited ‘Working’ areas.

- Our kerbs are very simple to mount

- Our kerb…. is one long “kerb”

- Costs are normally 1/2 of a standard kerb price

- Landscape architects can now draw any formate, turn or dream as they wish on the drawingbord -we can do the kerbing as you can see on our gallery

- We can lay kerbs on top of old asphalt – and save money for our customers

Advantages of our product over conventional kerbs:

- There’s no heaving lifting, you make the concrete yourself.

- You can apply any Kerb-mould (shapes) that your customer wants.

- You can make any turns, last minute changes, whatever!

- You can alternate from one type of kerb to another just by changing the mould.

- No wasted product, because you mix only what you are able to use.

- All our commercial kerbs are laid with a minimum of 2 stainless steel wires for extra reinforcement.

To date we have laid many kilometres of commercial kerbing both in ‘standard type kerbs’ and ‘Custom designed kerbs’. We work from our clients drawings and always deliver a first class job, of which they are pleasantly surprised from the speed, cleanliness, and the overall end result of the project.

Satisfied customers of our commercial Kerbing vary from location to location. A few to mention:

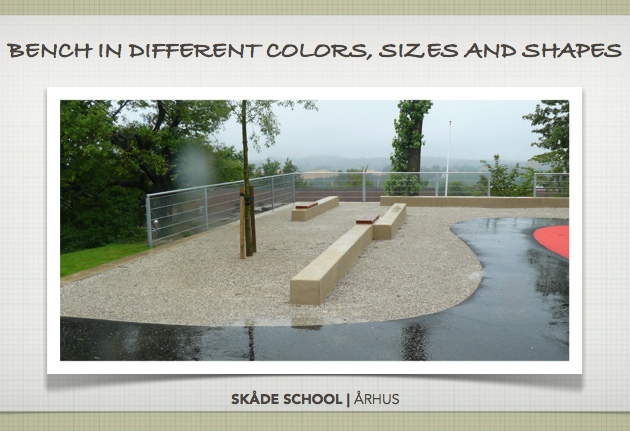

Schools, Playgrounds, Kindergarden, Churches, Parks, Parking lots, Parking garage, Housing estates, Local Communitys, Retning walls, Watergullys, Town furniture, Benches

This pictures show a project before and after, day we have finished the job. Project: kindergarden in Sweden in association with Karlskrona kommun and Landscape architects Kragh & Berglund.

In this parking lot we made 10×15 Kerbs with two steel wires. The kerbs are laid on top of 30 cm compressed sand and stone base: this type of kerbing process is very quick and easy to do. We completed this project at a 1/3 of the cost that the customer had budgeted for. Our price: 22 euro per meter!

When we lay kerbs directly on asphalt we nail the kerbs to the asphalt spikes. On top of that we always use steel wires in the kerbs.

At this school we first kerbed a water gully, then a few days later returned to lay the large 30 cm x 33 cm kerb – all in the same colour. Siena.

Often customers ask: “Are our kerbs strong enough for a car ?”

My answer is always ” YES – kerbs like ours have been made since the 1960’s all around the world”

Below two pictures are from a housing estate. The kerbs in the first picture were made with ‘wire and spikes’ on the asphalt. The second picture shows the kerbs with wire, but no spikes. As you can see the car tires have hit the kerb, and made ‘black marks’ putting a lot of stress on to the kerb – but the kerb still remains in position, and didn’t move a single mm.

This kerb was made with ‘wire and spikes’ on the asphalt.

This kerb was made with wire, but no spikes.

Another question we are often asked: “What will happen if the kerb breaks ?”

If an accident occurs, for example: A lorry hits the kerb with high speed and it breaks. Not to worry – It can be easily repaired. We knock the broken kerb out, and with our machine, we can repair it! If it is only a small repair, we just fix it with a hand trowl, or the customer himself can repair it.